Hose Pipe Pad Printing Machine Manufacturers, Suppliers, Exporters in Pune, Kolkata, Ahmedabad

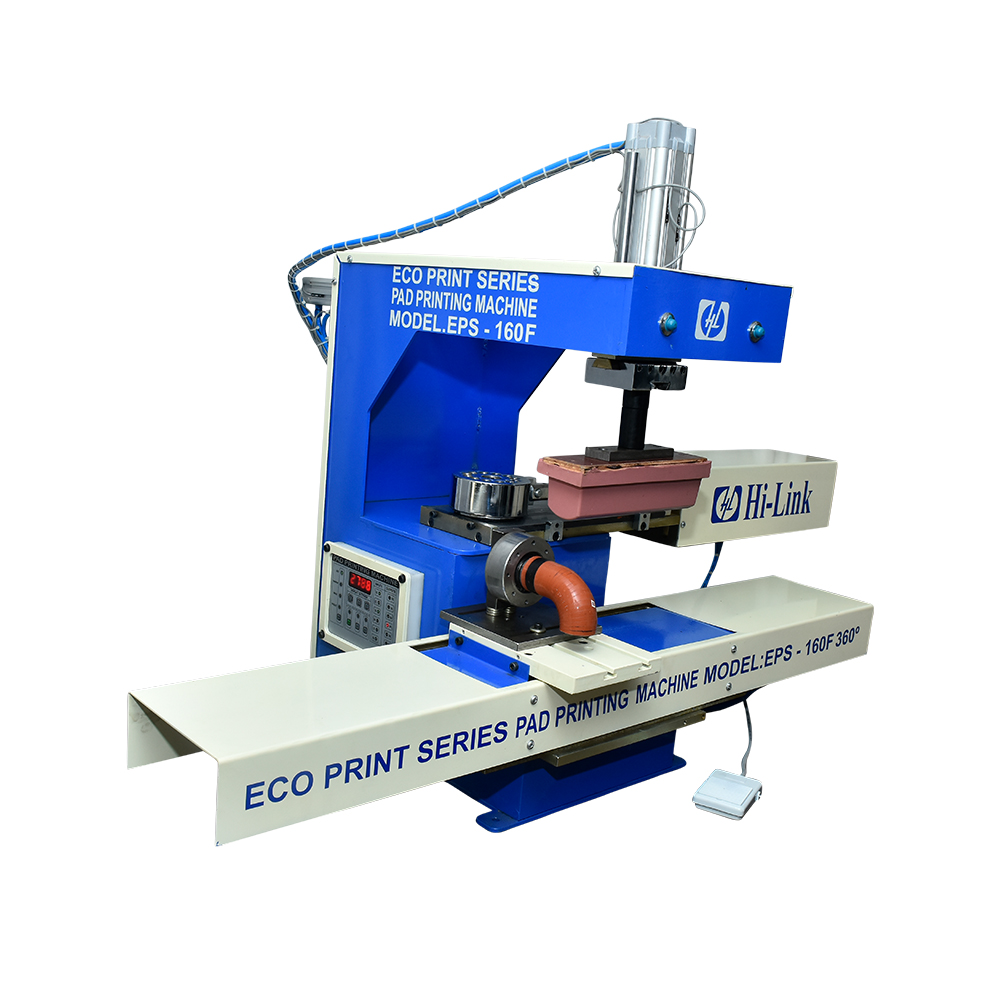

Hi Link Printing Technologies is the leading manufacturers, suppliers, exporters of Hose Pipe Pad Printing Machine, Rubber Hose Pad Printing Machine, and Rubber Tube Pad Printing Machine in Pune, Kolkata, Ahmedabad, Maharashtra, West Bengal, Gujarat. The Hose Pipe Pad Printing Machine is the printing machines that are used to print on rubber hose and rubber tube. These machines are designed to print on EPDM rubber, silicon rubber hose, and rubber tube.

Our machine is compact and has a voltage of 24V DC. We are the best Rubber Tube Pad Printing Machine manufacturers in Pune, Kolkata, and Ahmedabad serving the industry since the year 2013. Our rubber tube pad printing machine is an affordable pad printing machine that can be completely customized to meet specific requirements.

Rubber hose pad printing machine are easy to operate, user-friendly with advanced technology especially suited to printing on surfaces of any shape, texture, and composition with precise registration and high speed.

What is Hose Pipe Pad Printing Machine?

A hose pipe pad printing machine is a specialized printing device designed for applying customized designs, logos, or information onto hose pipes or similar cylindrical objects made of various materials like rubber, plastic, or metal. This machine employs a pad printing process, which is a versatile and precise method for transferring ink onto irregularly shaped surfaces.

How these Hose Pipe Pad Printing Machine Work?

Hose pipe pad printing machines work by using a silicone pad to transfer ink from an engraved plate (cliché) onto the curved surface of the hose pipe. The process involves several steps: -

- Ink Preparation: Ink is mixed and prepared to meet the specific requirements of the printing job.

- Cliché Preparation: The desired design or information is engraved onto a metal cliché plate.

- Ink Transfer: The ink is applied to the cliché plate, and an ink cup with a doctor blade scrapes excess ink, leaving only the ink in the engraved design.

- Pad Transfer: A silicone pad picks up the ink from the cliché and transfers it onto the hose pipe's surface.

- Drying or Curing: Depending on the ink used, the printed design is dried or cured to ensure it adheres to the hose pipe.

Key Features

- Cylindrical Printing Capability: These machines are specifically engineered to handle cylindrical objects, ensuring accurate and consistent printing on the curved surface of hose pipes.

- Adjustable Printing Parameters: Users can customize printing parameters such as ink viscosity, pad pressure, and drying time to accommodate different materials and printing requirements.

- Multiple Colors: Some models support multi-color printing, allowing for complex and vibrant designs.

- Automation: Advanced machines may include automation features like conveyor systems for continuous printing and robotic loading/unloading for increased efficiency.

- Precision: We offer high precision and accuracy, ensuring the design is aligned correctly on the hose pipe.

- Quick Setup: Many machines are designed for quick setup and changeovers between different hose pipe sizes and designs.

Product Details

| Product Name | Hose Pipe Pad Printing Machine/ Rubber Hose Pad Printing Machine/Rubber Tube Pad Printing Machine |

|---|---|

| Brand | Hi Link Printing |

| Printing Speed | Customized |

| Country of Origin | Made In India |

| Working Grade | Semi-Automatic |

| Usage | Printing Industry |